About Me

Hey, I'm Jason. I'm an automotive operations and technical analyst with 20+ years of experience diagnosing complex problems, coaching technicians, and supporting repair decisions in high-volume service environments. Throughout my career, I've been drawn to understanding patterns, identifying root causes, and making sense of operational data behind real-world decisions.

As a Technician Production Manager, I oversee technician workflow, approve repairs, and manage throughput while balancing cost, quality, and cycle time. I work closely with service advisors, operations leaders, and cross-functional teams to ensure repairs are appropriate, well-documented, and aligned with operational standards, while continuously looking for trends and opportunities to improve how the operation runs.

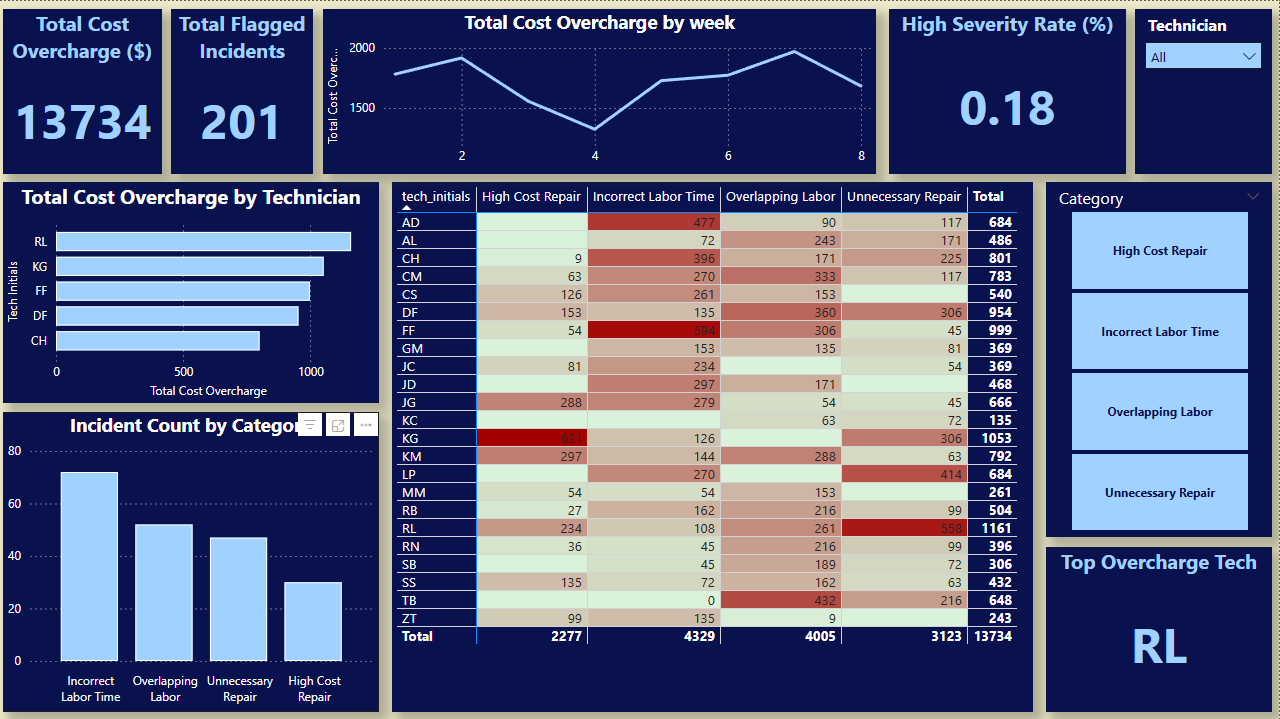

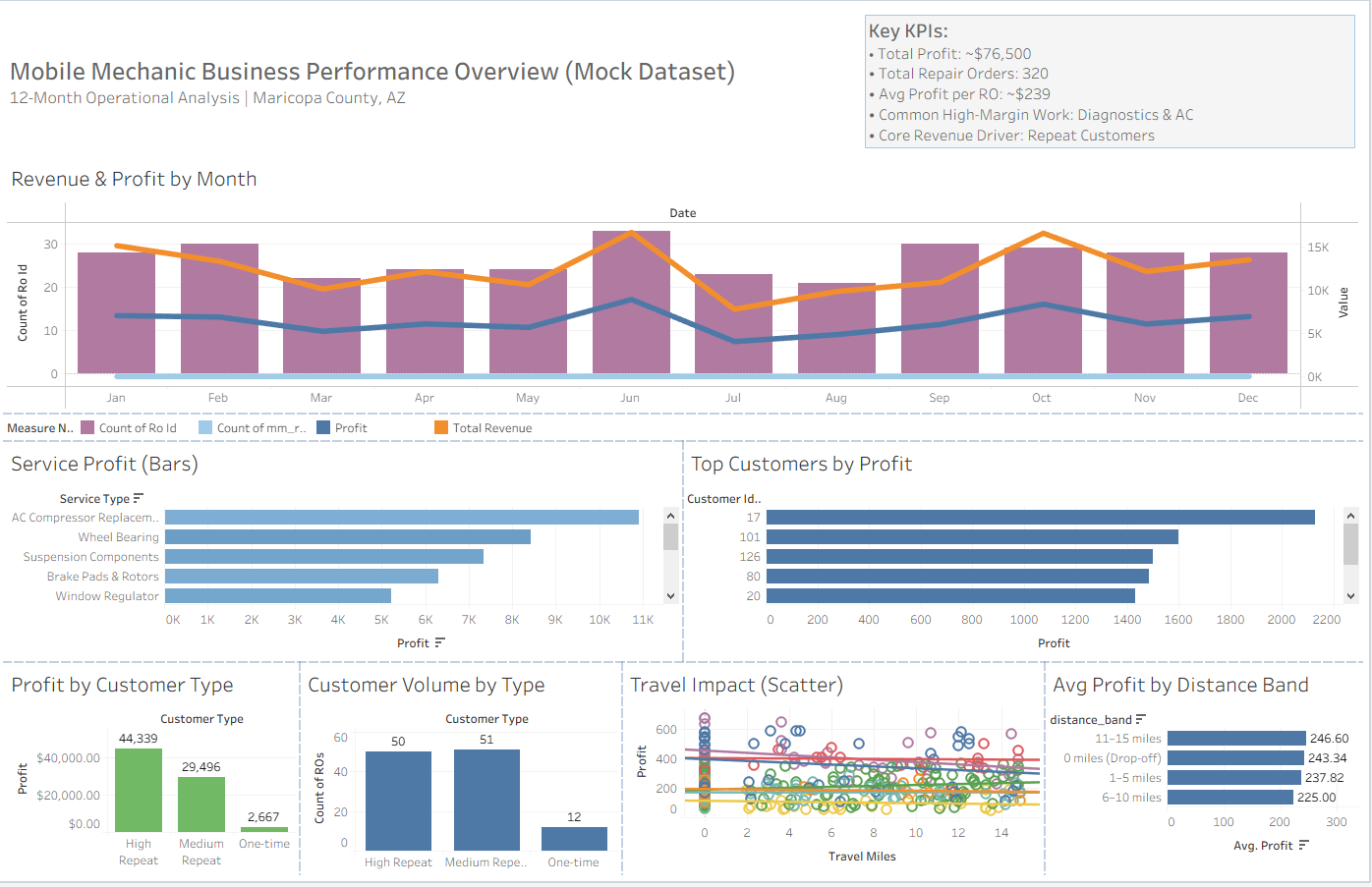

I'm currently part of a company-wide operational analysis initiative focused on labor usage and repair consistency. In this role, I review large volumes of repair order data to identify overlapping or misapplied labor, investigate trends, and present findings to senior leadership as part of a cost-reduction and process-clarity effort. This work sits at the intersection of technical judgment, attention to detail, and structured analysis.

Over the past several years, I've expanded my analytical toolkit to support this work, using Excel, SQL, Python, and BI tools to explore data, build dashboards, and translate operational complexity into clear, actionable insight. I use technology as a decision-support layer, not as an end in itself, grounded in practical service and operations experience.

I'm most effective in behind-the-scenes, collaborative roles where analytical thinking, technical understanding, and clear communication help organizations make better operational decisions. Connect with me on LinkedIn if you'd like to talk.

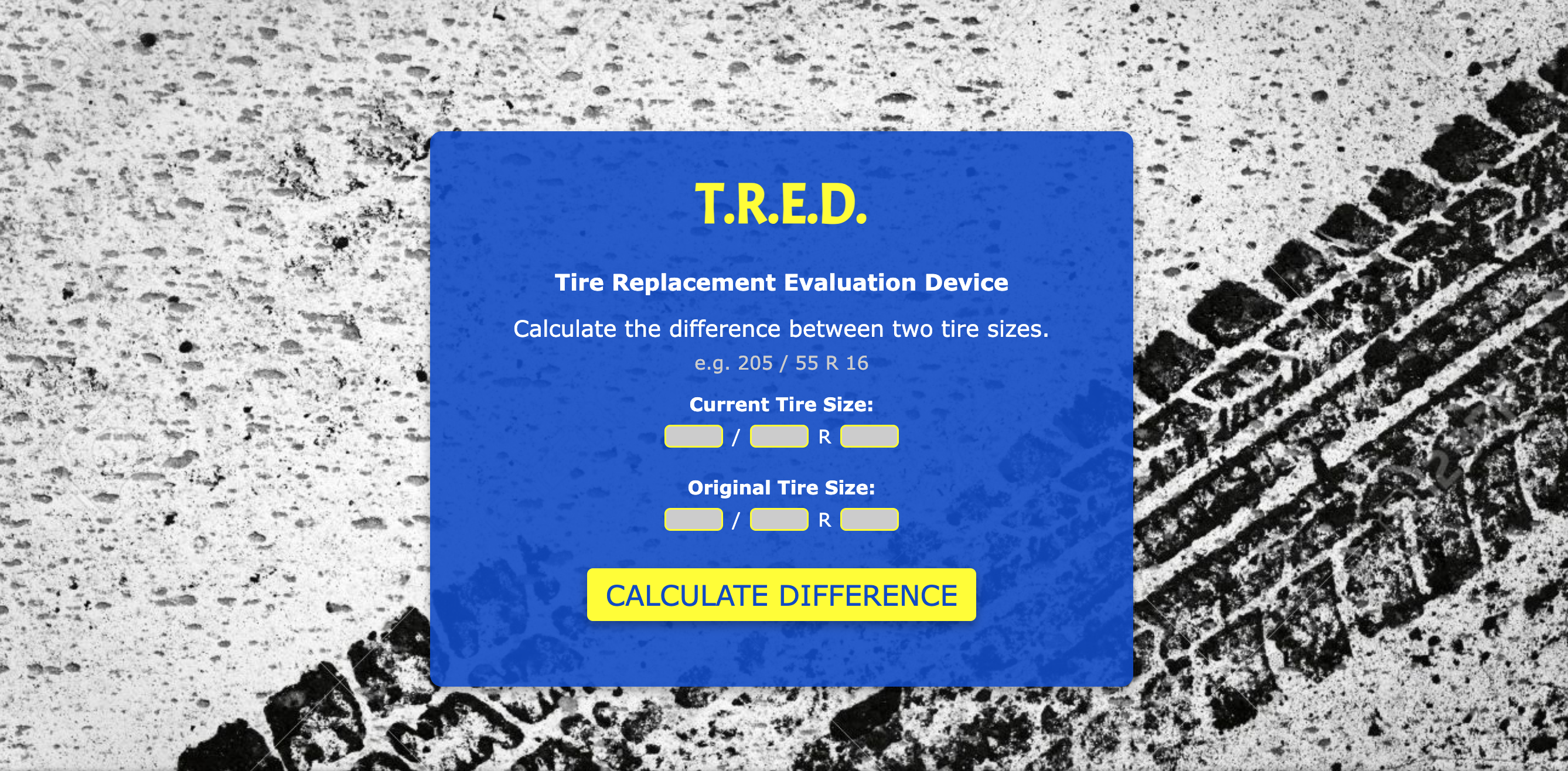

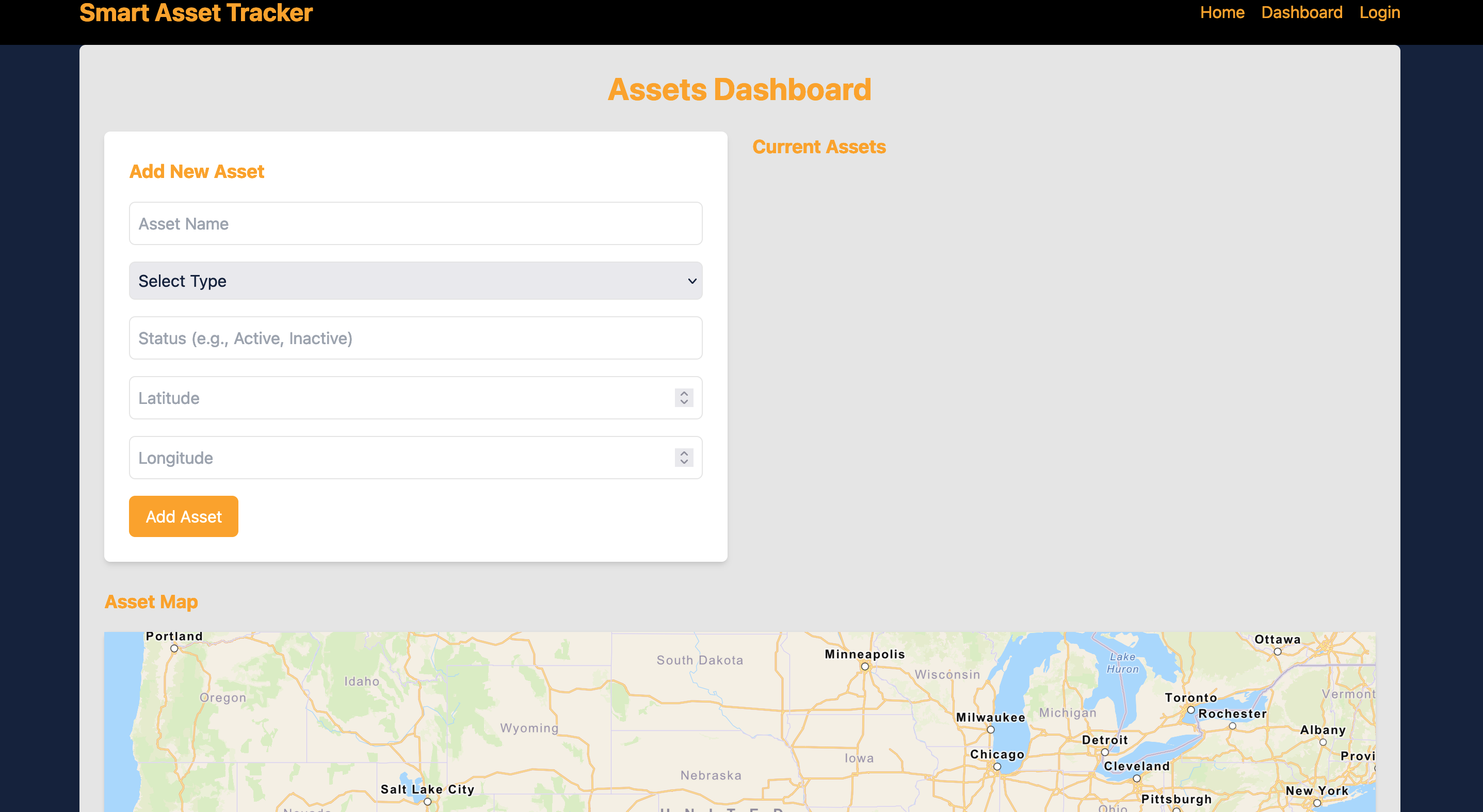

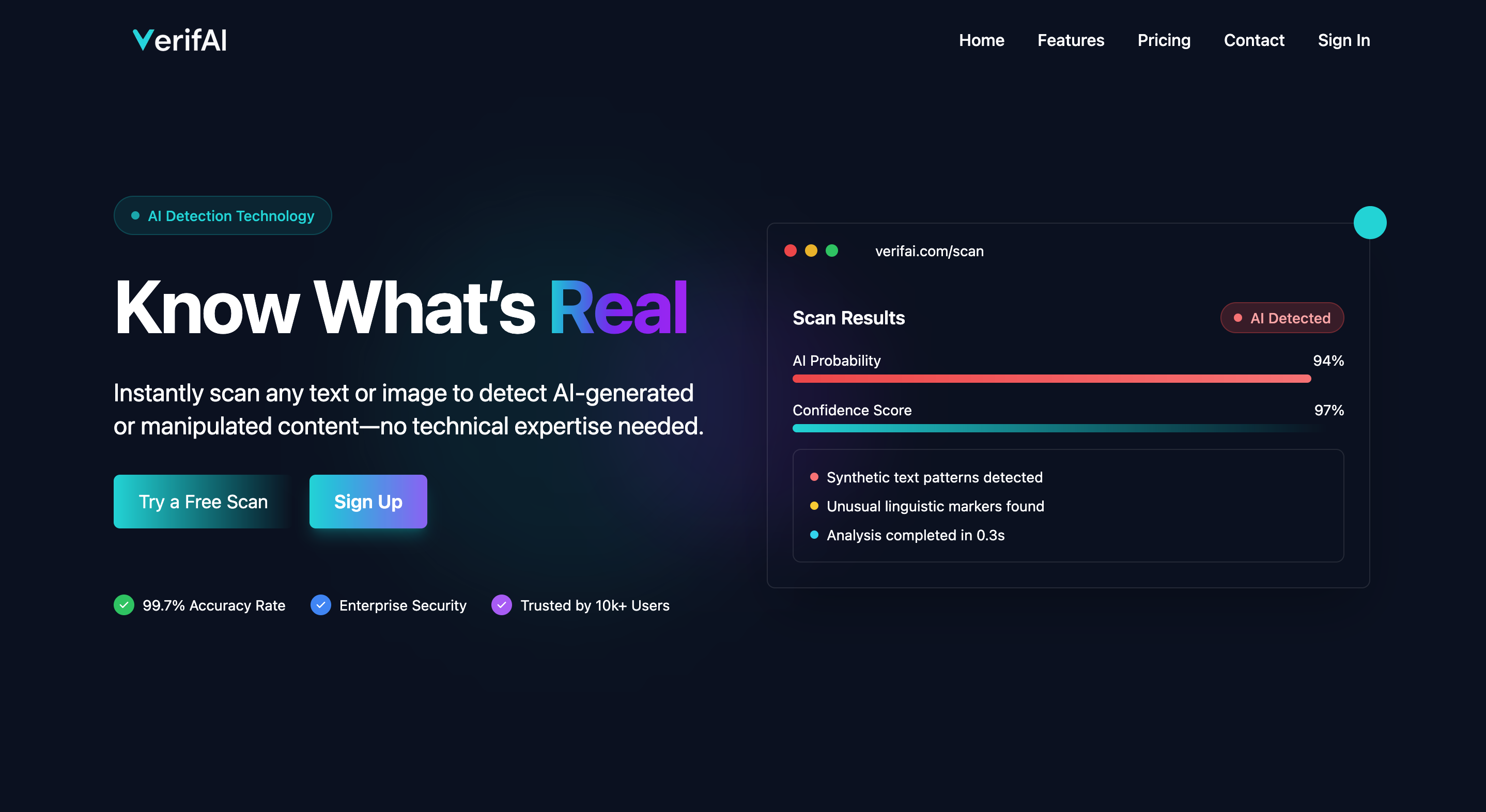

Analytics & Coding Activity

I regularly use modern analytics and development tools to build prototypes, dashboards, and automations that support analysis and decision making. Here's a snapshot of my recent GitHub activity: